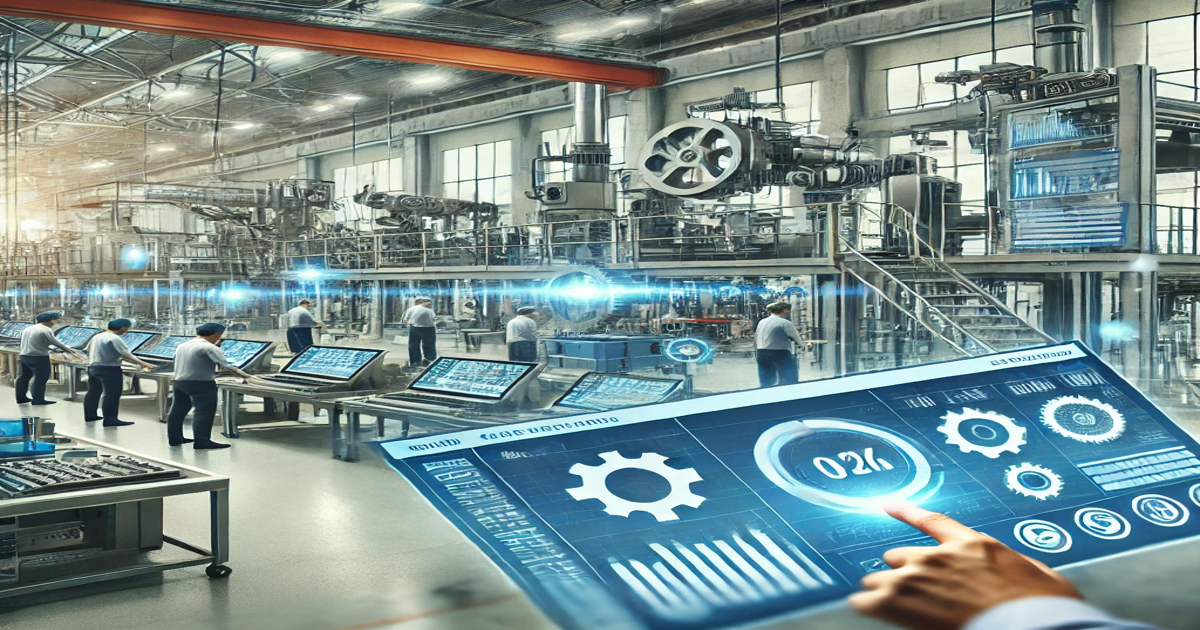

Unlocking the Power of Real-Time Data and Reporting in Beas Manufacturing with SAP Business One

In the fast-paced world of manufacturing, staying ahead of the curve is essential. One of the key elements driving this competitive edge is real-time data access and comprehensive reporting capabilities. For companies using Beas Manufacturing integrated with SAP Business One, these features can significantly enhance operational efficiency and decision-making. Let’s explore the benefits of real-time data and reporting in Beas Manufacturing.The Importance of Real-Time Data in Manufacturing

Real-time data refers to information that is delivered immediately after collection. There is no delay in the timeliness of the information provided. This capability is particularly crucial in the manufacturing sector, where conditions can change rapidly and decisions need to be made on the fly.Benefits of Real-Time Data Access:

- Enhanced Decision-Making:

- With real-time data, managers can make informed decisions quickly. This immediacy is critical for addressing issues such as machine breakdowns, inventory shortages, or quality control problems before they escalate.

- Improved Efficiency:

- Real-time data allows for better resource allocation. By having up-to-the-minute information on production status, companies can optimize their processes, reduce waste, and improve overall efficiency.

- Increased Agility:

- Manufacturing environments are dynamic. Real-time data enables companies to be more agile, adapting to changes in demand, supply chain disruptions, or other unforeseen events with minimal downtime.

Comprehensive Reporting Features in Beas Manufacturing

In addition to real-time data, comprehensive reporting is another critical feature of Beas Manufacturing when integrated with SAP Business One. Detailed and accurate reports provide deep insights into various aspects of the manufacturing process.Key Reporting Benefits:

- Holistic View of Operations:

- Comprehensive reports offer a complete view of the entire manufacturing operation. This holistic perspective helps in understanding how different processes interact and impact each other.

- Trend Analysis and Forecasting:

- Historical data and trend analysis reports can be used to forecast future demands and trends. This predictive capability helps in better planning and inventory management.

- Compliance and Quality Control:

- Detailed reports are essential for maintaining compliance with industry standards and regulations. They also help in tracking quality control measures and ensuring that products meet the required specifications.

- Cost Management:

- Reporting tools help in identifying areas where costs can be reduced without compromising on quality. By analyzing various cost factors, companies can implement cost-saving measures effectively.

Integration of Beas Manufacturing with SAP Business One

The integration of Beas Manufacturing with SAP Business One brings together powerful ERP capabilities with specialized manufacturing functionalities. This combination ensures that data flows seamlessly across the organization, providing a unified platform for managing all aspects of manufacturing operations.Enhanced Features with Integration:

- Streamlined Operations:

- The integration ensures that data from various sources is consolidated, providing a single source of truth. This streamlines operations and reduces the complexity of managing multiple systems.

- Real-Time Collaboration:

- Teams can collaborate more effectively with real-time data and reporting. This collaboration leads to better coordination and alignment of goals across departments.

- Scalability:

- As the business grows, the integrated system can scale accordingly. This scalability ensures that the company can handle increased workloads and maintain efficiency.