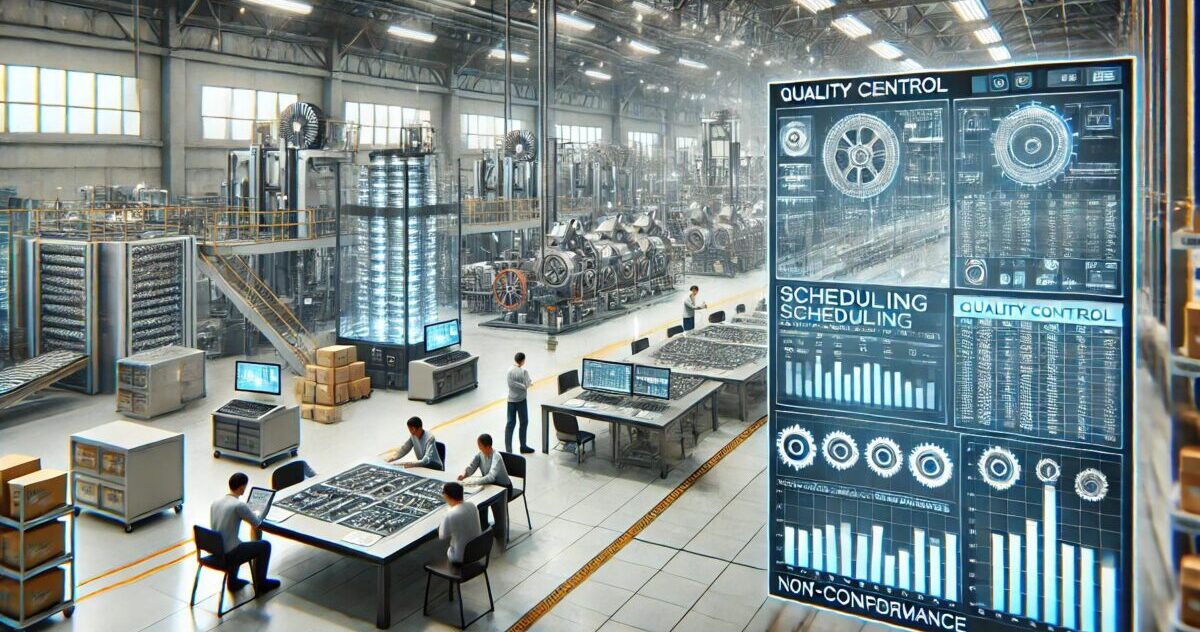

In today’s fast-paced business world, efficient scheduling and strong quality assurance are vital for success. Boyum’s BEAS solution, tailored for manufacturing and production companies, stands out as a powerful tool that can transform these essential aspects of your business. In this blog post, we’ll explore how BEAS can improve your scheduling efficiency and enhance your quality assurance processes, ultimately driving your business toward greater productivity and customer satisfaction.

Understanding Boyum’s BEAS Solution

Boyum’s BEAS (Boyum Advanced Manufacturing Solution) is a complete suite designed for SAP Business One, addressing the unique challenges of manufacturing industries. It seamlessly connects with your existing ERP system, offering strong features for planning, scheduling, and quality control. By using BEAS, businesses can streamline their manufacturing processes, cut waste, and ensure products meet the highest quality standards.

The Importance of Effective Scheduling

Effective scheduling forms the backbone of any manufacturing operation. It ensures that resources are used efficiently, production timelines are met, and customer orders arrive on time. Without proper scheduling, you might face bottlenecks, overproduction, increased costs, and unhappy customers. This is where BEAS makes a big difference.

How BEAS Enhances Scheduling Efficiency

Advanced Planning and Scheduling (APS): BEAS provides Advanced Planning and Scheduling tools that let businesses create detailed production schedules. This module considers factors like machine capacities, labor availability, and material limits, ensuring that schedules are realistic and achievable.

Real-time Data Integration: One standout feature of BEAS is its ability to connect real-time data from the shop floor. This means any changes in production status, machine downtimes, or labor availability show up instantly in the scheduling system. Consequently, this real-time view helps businesses make quick, informed decisions and adapt schedules to meet changing production needs.

Resource Optimization: BEAS makes the best use of resources by ensuring machines and labor are fully utilized. It cuts idle times and reduces the need for overtime, which not only boosts productivity but also lowers operational costs.

Scenario Planning: Additionally, the solution lets businesses simulate different scheduling scenarios before implementing them. This feature is invaluable for seeing the impact of potential changes, such as adding a new product line or changing production shifts, on overall production efficiency.

Elevating Quality Assurance with BEAS

Quality assurance is another key area where BEAS shines. In a highly competitive market, keeping product quality consistent is essential for retaining customers and building a strong brand reputation.

Integrated Quality Control: BEAS brings quality control directly into the production process. You can schedule quality checks at various stages of production, ensuring that any defects are found and fixed promptly. This proactive approach lowers the risk of defective products reaching customers.

Automated Documentation: Moreover, the solution automates the documentation process for quality assurance. It records test results, generates inspection reports, and maintains compliance records. Automated documentation saves time and ensures records are accurate and easy to access for audits and reviews.

Non-conformance Management: BEAS also offers tools for managing non-conformances effectively. When a defect is found, the system creates a non-conformance report, tracks the issue, and starts corrective actions. This systematic approach ensures that issues are resolved quickly and that preventive measures are put in place to avoid recurrence.

Traceability: Furthermore, traceability is a key part of quality assurance, especially in industries like food, pharmaceuticals, and automotive. BEAS provides strong traceability features, allowing businesses to track products and components throughout the entire supply chain. This capability is crucial for finding the root cause of quality issues and implementing targeted solutions.

Real-world Benefits of BEAS

Increased Production Efficiency: By optimizing scheduling and resource allocation, BEAS helps businesses increase their production efficiency. This leads to shorter lead times, higher throughput, and the ability to meet customer demands more effectively.

Reduced Operational Costs: Efficient scheduling and resource use significantly cut operational costs. Businesses can minimize overtime, reduce waste, and avoid costs related to production delays and quality issues.

Enhanced Product Quality: With integrated quality control and traceability, BEAS ensures that products meet the highest quality standards. This leads to higher customer satisfaction, fewer returns, and a stronger brand reputation.

Regulatory Compliance: Additionally, automated documentation and traceability features help businesses stay compliant with industry regulations and standards. This is especially important for businesses operating in highly regulated industries.

Conclusion

In today’s competitive business landscape, efficient scheduling and strong quality assurance are not just desirable—they are essential. Boyum’s BEAS solution provides a complete set of tools that address these critical areas, helping businesses streamline their operations and maintain high standards of product quality. By integrating BEAS into your manufacturing processes, you can achieve greater efficiency, reduce costs, and enhance customer satisfaction, ultimately driving your business toward sustained success.

Incorporating Boyum’s BEAS into your business strategy can be a game-changer. If you’re ready to take your scheduling and quality assurance processes to the next level, it’s time to explore what BEAS can do for you.